Vizag Chemical: Spearheading the Ethylene-Propylene Rubber Industry in India

Amidst the rich tapestry of India's industrial realm, Vizag Chemical emerges as a trailblazer in the production and distribution of Ethylene-Propylene Rubber (EPR). Situated in the heart of the subcontinent, it represents the perfect blend of tradition and innovation, offering premium-grade rubber solutions tailored for the modern world.

Formula: Ethylene (C2H4) and Propylene (C3H6)

Product Description:

Ethylene-Propylene Rubber, a copolymer, is the brainchild of combining ethylene and propylene. Renowned for its stellar resilience, elasticity, and resistance, Vizag Chemical ensures its EPR remains at the forefront of quality and performance.

Usage and Application:

Ethylene-propylene rubber (EPR), also known as EPDM (ethylene-propylene-diene monomer), is a versatile synthetic rubber with a wide range of applications across various sectors. EPR is known for its excellent resistance to weather, ozone, heat, and chemicals, making it suitable for both indoor and outdoor applications. This report explores the applications and uses of ethylene-propylene rubber in different sectors, covering its properties, production methods, and advantages in each application.

1. Automotive Industry: Ethylene-propylene rubber is extensively used in the automotive industry due to its durability, resistance to weathering, and versatility.

- Weather Seals and Gaskets: EPDM is used in weather seals, gaskets, and window seals in vehicles to prevent leaks and provide insulation.

- Radiator Hoses: EPDM is used in radiator hoses due to its heat resistance and ability to withstand the effects of engine fluids.

- Tire Sidewalls: EPDM is used in tire sidewalls for its resistance to UV radiation and weathering, enhancing the tire's lifespan.

- Door Seals: EPDM is used in door seals to prevent moisture and air infiltration, contributing to passenger comfort.

2. Construction and Building Materials: Ethylene-propylene rubber is utilized in construction for its resistance to weather, UV radiation, and chemicals.

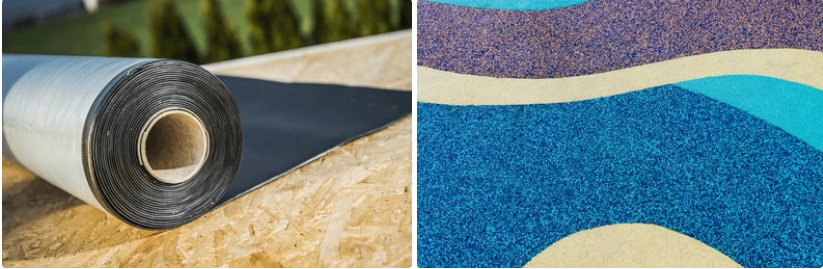

- Roofing Membranes: EPDM is used in roofing membranes for its waterproofing properties and durability in various weather conditions.

- Expansion Joints: EPDM is used in expansion joints to accommodate movement and seal gaps in building materials.

- Sealants and Adhesives: EPDM is used in sealants and adhesives for construction applications due to its ability to bond and seal materials effectively.

3. Electrical and Electronics: Ethylene-propylene rubber is used in the electrical and electronics industry for its insulating and sealing properties.

- Cable Insulation: EPDM is used as cable insulation in electrical wiring for its ability to provide electrical insulation and withstand temperature variations.

- Electrical Sealing: EPDM is used to seal electrical enclosures and connectors, protecting them from moisture and environmental elements.

4. Automotive Aftermarket: Ethylene-propylene rubber finds applications in the automotive aftermarket sector for replacement parts and repairs.

- Seals and O-rings: EPDM is used in the production of replacement seals, gaskets, and O-rings for automotive repairs.

- Rubber Mats and Liners: EPDM is used to create rubber mats, liners, and floor coverings for vehicles to protect interiors from moisture and wear.

5. Marine Industry: Ethylene-propylene rubber is used in the marine sector due to its resistance to saltwater, UV radiation, and environmental factors.

- Boat Fenders: EPDM is used in boat fenders and bumpers to provide cushioning and protection against impacts.

- Marine Seals: EPDM is used in marine seals and gaskets to prevent water intrusion and corrosion in marine equipment.

6. HVAC and Plumbing: Ethylene-propylene rubber is used in heating, ventilation, air conditioning (HVAC), and plumbing applications.

- Pipe Seals: EPDM is used in pipe seals to prevent leaks in plumbing systems and HVAC installations.

- Cooling Tower Gaskets: EPDM is used in cooling tower gaskets for its resistance to water, heat, and chemicals.

7. Industrial Seals and Gaskets: Ethylene-propylene rubber is used in various industrial sectors for sealing and gasket applications.

- Industrial Equipment: EPDM is used in industrial equipment for sealing and gasketing, preventing leaks and maintaining operational integrity.

- Process Plant Components: EPDM is used in process plant components such as valves and pumps for its resistance to chemicals and heat.

8. Agriculture and Horticulture: Ethylene-propylene rubber finds applications in agriculture and horticulture due to its resistance to weather and chemicals.

- Agricultural Equipment: EPDM is used in agricultural equipment components such as belts, hoses, and gaskets for its durability and performance in outdoor environments.

- Greenhouse Seals: EPDM is used in greenhouse seals and gaskets to create a controlled environment for plant growth.

9. Sports and Recreation: Ethylene-propylene rubber is used in sports and recreational equipment due to its durability and weather resistance.

- Sports Surfaces: EPDM is used in sports surfaces such as tracks and playgrounds for its shock absorption and weather resistance.

- Recreational Equipment: EPDM is used in recreational equipment such as mats and flooring for its ability to provide a safe and comfortable surface.

10. Aerospace Industry: Ethylene-propylene rubber is used in the aerospace sector for its resistance to high and low temperatures.

- Aircraft Seals: EPDM is used in aircraft seals and gaskets to maintain pressure differentials and prevent leaks in various aircraft components.

- Spacecraft Components: EPDM is used in spacecraft components for its ability to withstand the extreme temperature fluctuations of space environments.

ethylene-propylene rubber (EPDM) is a versatile material with a wide range of applications across different sectors. Its properties, including weather resistance, UV resistance, chemical resistance, and durability, make it valuable in the automotive industry, construction, electrical and electronics, marine applications, HVAC and plumbing, industrial sectors, agriculture, sports and recreation, and the aerospace industry. As industries continue to evolve and prioritize performance, efficiency, and sustainability, the applications of ethylene-propylene rubber are likely to expand further, reinforcing its role as a critical component in modern manufacturing and technology.

Product Parameters:

- Grade Standard: Encompassing automotive, industrial, and pharmaceutical standards.

- Certification: Proudly flaunting global certifications like ISO, ASTM, and others.

- Purity: Ensured through rigorous refinement processes.

- Appearance: Demonstrating consistent and superior quality.

Specifications:

Derived from stringent international benchmarks, which include properties such as tensile strength, elasticity, and temperature resistance.

Our Advantages:

- Location: Nestled in Vizag, offering strategic advantages in transportation and distribution.

- Expertise: Pioneers with decades of experience.

- Global Presence: Marking our footprint across major global hubs - Dubai, London, Shanghai, New York, Riyadh, to name a few.

Production Capacity:

A testament to its vast infrastructure, Vizag Chemical stands ready to cater to the surging global demands for EPR.

Quality Control:

Uncompromised and unmatched - every batch of EPR is subjected to rigorous checks to ensure global standards.

Customization:

Meeting unique demands with tailored EPR solutions that fit the specific needs of different industries.

Company Info:

A beacon of India's indomitable spirit of entrepreneurship and innovation, Vizag Chemical transcends the boundaries of a regular enterprise, touching the very core of the industry it serves.

Packing:

With top-of-the-line packaging solutions, EPR from Vizag Chemical reaches its destination in immaculate condition.

Physical Properties:

- Density: Typically around 0.86 g/cm³.

- Melting Point: Showcasing unparalleled thermal resilience.

- Elongation at Break: Exemplifying its elasticity.

Storage:

Employs cutting-edge storage facilities, ensuring the longevity and retention of EPR's quality.

Quality Inspection:

Advanced inspection mechanisms that employ the latest technologies ensure Vizag Chemical's products stand second to none.

Plant Area:

Spread across vast acres, the facility of Vizag Chemical is a harmonious blend of technology and efficiency.

Terms of Payment or Quotation & Payment:

Designed keeping in mind client convenience, the company offers a wide array of payment options.

Nearest Port:

Strategically located near major ports, ensuring seamless transportation logistics.

Import & Export Mode:

Flexible modes from CIF to FOB guarantee a seamless trade experience across borders.

Vizag Chemical isn't just a name; it's a legacy. A saga of how an Indian enterprise, rooted in Vizag, took on the global challenge and emerged as a vanguard in the Ethylene-Propylene Rubber industry. With its gaze firmly set on the future and its foundation steeped in tradition, Vizag Chemical exemplifies the essence of India - an age-old civilization always on the brink of the future. As it continues to weave its story, one thing remains certain - wherever there's a need for top-quality EPR, Vizag Chemical will be there, bridging gaps and building futures.

For inquiries and orders, please get in touch with us at Email-

info@vizagchemical.com

Leave a comment