Vizag Chemical: Your Reliable Potassium Silicate Supplier in India

Potassium silicate, also known as potassium water glass or potassium silicate solution, is an inorganic compound with various applications and uses across different sectors. It is formed by the reaction of potassium hydroxide with silica or silica sand. Here is an in-depth exploration of the applications and uses of potassium silicate in different sectors:

-

Agriculture:

- Soil Stabilization: Potassium silicate is used to stabilize soil, particularly in sandy or loose soil conditions. It helps improve soil structure, increases water retention, and enhances nutrient availability for plant growth.

- Plant Nutrient Source: Potassium silicate can serve as a source of both potassium and silicon, which are essential nutrients for plant development. It contributes to better root development, disease resistance, and overall plant health.

- pH Buffer: Potassium silicate acts as a pH buffer in hydroponic systems and soilless growing media. It helps maintain the desired pH range for optimal nutrient absorption by plants.

-

Cement and Construction:

- Concrete Admixture: Potassium silicate can be used as an admixture in cement and concrete formulations. It enhances the strength, durability, and chemical resistance of concrete structures.

- Surface Hardener: Potassium silicate is utilized as a surface hardener for concrete floors and pavements. It forms a protective layer that increases abrasion resistance and reduces dusting.

-

Coatings and Paints:

- Protective Coatings: Potassium silicate is used in the production of protective coatings for various surfaces, including metals, masonry, and wood. It provides excellent adhesion, chemical resistance, and weatherproofing properties.

- Fireproof Coatings: Potassium silicate coatings can act as fire-resistant barriers on surfaces. They provide thermal insulation and help prevent the spread of flames in case of fire.

-

Ceramic and Glass Industry:

- Potassium silicate is employed as a binder and fluxing agent in the production of ceramics and glass. It helps improve the workability of ceramic bodies, enhances adhesion between layers, and lowers the melting temperature of glass.

-

Textile and Fiber Industry:

- Flame Retardant Treatment: Potassium silicate is used as a flame retardant in textiles and fibers. It can be applied to fabrics or incorporated into fiber production processes to improve fire resistance.

-

Detergent and Cleaning Products:

- Potassium silicate is used in detergent formulations as a builder and water softener. It enhances the cleaning efficiency by preventing the deposition of mineral scale and improving the solubility of other ingredients.

-

Metal Treatment:

- Metal Casting: Potassium silicate is used as a binder in the casting process of metals. It helps hold sand molds together and provides dimensional stability during metal pouring.

- Corrosion Inhibitor: Potassium silicate can be employed as a corrosion inhibitor for metals. It forms a protective film on the metal surface, preventing corrosion and extending the lifespan of the metal.

-

Adhesives and Sealants:

- Potassium silicate-based adhesives and sealants are used in various applications, including bonding, sealing, and gap-filling. They offer good adhesion to different substrates and provide resistance to heat, moisture, and chemicals.

-

Electronics and Electrical Industry:

- Potassium silicate is used in the production of electrical insulators and encapsulation materials. It provides thermal stability, electrical insulation, and protection against moisture and environmental contaminants.

-

Paper Industry:

- Potassium silicate can be used as a paper coating agent to enhance the surface properties of paper, such as smoothness, brightness, and ink absorption.

-

Horticulture and Greenhouses:

- Potassium silicate is applied in horticulture as a foliar spray or root drench to enhance plant growth, improve disease resistance, and increase tolerance to environmental stresses.

-

Water Treatment:

- Potassium silicate is occasionally used in water treatment processes for certain applications. It can help stabilize pH levels, reduce heavy metal concentrations, and enhance the coagulation and flocculation processes.

It is important to follow appropriate safety precautions while handling potassium silicate, as it can be corrosive in its concentrated form. Dilution and proper protective equipment should be used to ensure safe usage and handling.

Vizag Chemical, your trusted potassium silicate supplier, manufacturer, and distributor in India. With a commitment to quality, reliability, and customer satisfaction, we provide high-grade potassium silicate products to cater to various industries.

Product Details:

- CAS NO: 1312-76-1

- Formula: K2SiO3

- Product Description: Potassium silicate is an inorganic compound that appears as a colorless or slightly yellowish liquid or solid. It is a versatile chemical widely used in numerous industries for its adhesive, binding, and protective properties.

Usage and Applications:

Potassium silicate, also known as potassium water glass or potassium silicate solution, is an inorganic compound with various applications and uses across different sectors. It is formed by the reaction of potassium hydroxide with silica or silica sand. Here is an in-depth exploration of the applications and uses of potassium silicate in different sectors:

-

Agriculture:

- Soil Stabilization: Potassium silicate is used to stabilize soil, particularly in sandy or loose soil conditions. It helps improve soil structure, increases water retention, and enhances nutrient availability for plant growth.

- Plant Nutrient Source: Potassium silicate can serve as a source of both potassium and silicon, which are essential nutrients for plant development. It contributes to better root development, disease resistance, and overall plant health.

- pH Buffer: Potassium silicate acts as a pH buffer in hydroponic systems and soilless growing media. It helps maintain the desired pH range for optimal nutrient absorption by plants.

-

Cement and Construction:

- Concrete Admixture: Potassium silicate can be used as an admixture in cement and concrete formulations. It enhances the strength, durability, and chemical resistance of concrete structures.

- Surface Hardener: Potassium silicate is utilized as a surface hardener for concrete floors and pavements. It forms a protective layer that increases abrasion resistance and reduces dusting.

-

Coatings and Paints:

- Protective Coatings: Potassium silicate is used in the production of protective coatings for various surfaces, including metals, masonry, and wood. It provides excellent adhesion, chemical resistance, and weatherproofing properties.

- Fireproof Coatings: Potassium silicate coatings can act as fire-resistant barriers on surfaces. They provide thermal insulation and help prevent the spread of flames in case of fire.

-

Ceramic and Glass Industry:

- Potassium silicate is employed as a binder and fluxing agent in the production of ceramics and glass. It helps improve the workability of ceramic bodies, enhances adhesion between layers, and lowers the melting temperature of glass.

-

Textile and Fiber Industry:

- Flame Retardant Treatment: Potassium silicate is used as a flame retardant in textiles and fibers. It can be applied to fabrics or incorporated into fiber production processes to improve fire resistance.

-

Detergent and Cleaning Products:

- Potassium silicate is used in detergent formulations as a builder and water softener. It enhances the cleaning efficiency by preventing the deposition of mineral scale and improving the solubility of other ingredients.

-

Metal Treatment:

- Metal Casting: Potassium silicate is used as a binder in the casting process of metals. It helps hold sand molds together and provides dimensional stability during metal pouring.

- Corrosion Inhibitor: Potassium silicate can be employed as a corrosion inhibitor for metals. It forms a protective film on the metal surface, preventing corrosion and extending the lifespan of the metal.

-

Adhesives and Sealants:

- Potassium silicate-based adhesives and sealants are used in various applications, including bonding, sealing, and gap-filling. They offer good adhesion to different substrates and provide resistance to heat, moisture, and chemicals.

-

Electronics and Electrical Industry:

- Potassium silicate is used in the production of electrical insulators and encapsulation materials. It provides thermal stability, electrical insulation, and protection against moisture and environmental contaminants.

-

Paper Industry:

- Potassium silicate can be used as a paper coating agent to enhance the surface properties of paper, such as smoothness, brightness, and ink absorption.

-

Horticulture and Greenhouses:

- Potassium silicate is applied in horticulture as a foliar spray or root drench to enhance plant growth, improve disease resistance, and increase the tolerance to environmental stresses.

-

Water Treatment:

- Potassium silicate is occasionally used in water treatment processes for certain applications. It can help stabilize pH levels, reduce heavy metal concentrations, and enhance the coagulation and flocculation processes.

It is important to follow appropriate safety precautions while handling potassium silicate, as it can be corrosive in its concentrated form. Dilution and proper protective equipment should be used to ensure safe usage and handling.

Product Parameters:

- Grade Standard: Industrial Grade

- Certification: ISO 9001:2015 certified

- Purity: High purity with a minimum of 98%

- Appearance: Colorless or slightly yellowish liquid or solid

Specifications:

- pH Value: 10-12

- Potassium Content (K2O): 20-22%

- Silicon Dioxide (SiO2): 25-28%

- Density: 1.85-1.95 g/cm³

- Viscosity: 10-50 cP (centipoise)

- Solubility: Fully soluble in water

Our Advantages:

- Quality Assurance: Our potassium silicate products undergo stringent quality control measures to ensure consistent purity and performance.

- Wide Application Range: We cater to diverse industries, offering customized potassium silicate solutions to meet specific requirements.

- Competitive Pricing: We strive to provide cost-effective solutions without compromising on quality.

- Timely Delivery: We have a robust supply chain network, enabling us to deliver products promptly.

- Technical Support: Our experienced team is available to assist you with technical queries and product recommendations.

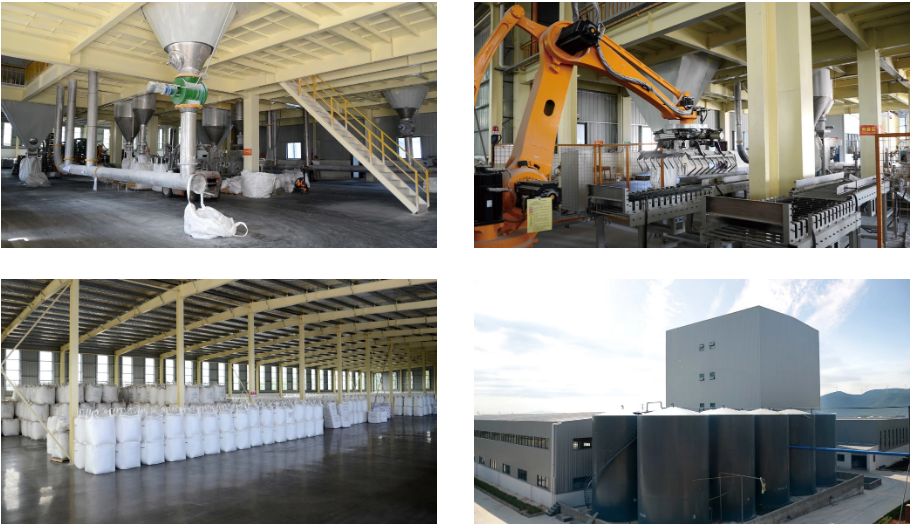

Company Information: Vizag Chemical is a leading supplier and manufacturer of potassium silicate in India. With several years of industry experience, we have earned a reputation for providing reliable products and excellent customer service. Our state-of-the-art manufacturing facility, located in Visakhapatnam, spans over 10,000 square meters and adheres to strict quality control standards.

Packing, Plant Area, and Terms of Payment:

- Packing: Available in 50 kg HDPE drums or as per customer requirements.

- Plant Area: Our manufacturing plant occupies a sprawling area of 10,000 square meters, equipped with advanced production facilities.

- Terms of Payment: We accept various payment modes, including online transfers, bank drafts, and letters of credit.

Nearest Port and Import/Export Mode:

- Nearest Port: Visakhapatnam Port, situated on the east coast of India, is the nearest port for convenient shipping.

- Import & Export Mode: We operate in both import and export modes, catering to clients across the Middle East and the world.

Conclusion: Vizag Chemical is your trusted partner for high-quality potassium silicate products in India. Our commitment to superior quality, technical expertise, and customer satisfaction sets us apart. With a wide range of applications and excellent product parameters, we cater to diverse industries. Contact us today to discuss your potassium silicate requirements and experience our top-notch products and services.

Leave a comment