Polyacrylonitrile Supplier, Manufacturer, and Distributor in India

Welcome to Vizag Chemical, your reliable source for high-quality Polyacrylonitrile (PAN) products in India. As a leading supplier, manufacturer, and distributor, we are committed to delivering a comprehensive range of PAN products that cater to diverse industries.

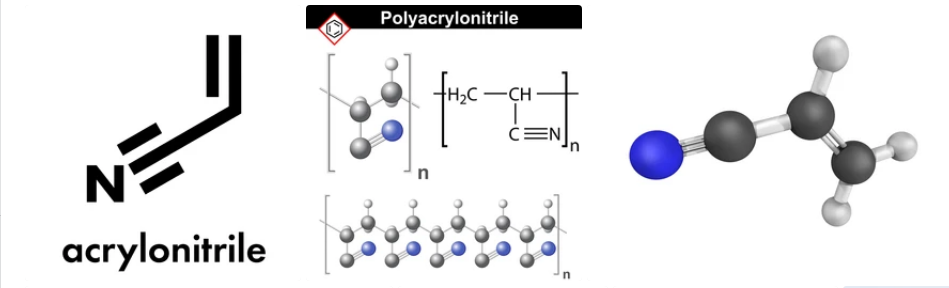

CAS NO: 25014-41-9 Formula: (C3H3N)n

Product Description: Polyacrylonitrile, commonly known as PAN, is a synthetic polymer produced from acrylonitrile monomers. This versatile material exhibits remarkable properties such as high tensile strength, chemical resistance, and thermal stability. At Vizag Chemical, we offer PAN products in various forms, including fibers, resins, and films, ensuring widespread applicability.

Usage and Application:

Polyacrylonitrile (PAN) is a synthetic polymer with a wide range of applications across various sectors due to its unique properties and versatility. PAN is a type of acrylic resin and is commonly used in industries ranging from textiles to aerospace. In this comprehensive report, we will explore the applications and uses of Polyacrylonitrile in different sectors, covering its properties, processing methods, and advantages in each application.

- Textile Industry: The textile industry is one of the major consumers of Polyacrylonitrile. PAN fibers are commonly used to produce acrylic fabrics, which offer excellent softness, warmth, and a wool-like appearance. Acrylic fabrics have the following advantages:

- Resistance to sunlight: Acrylic fabrics have better resistance to UV rays compared to natural fibers, making them suitable for outdoor applications like awnings and outdoor furniture.

- Colorfastness: Acrylic fabrics retain their color well and are less prone to fading, making them ideal for use in vibrant and long-lasting clothing.

- Moisture-wicking: Acrylic fibers have moisture-wicking properties, making them suitable for sportswear and activewear.

- Ease of care: Acrylic fabrics are relatively easy to clean and maintain, reducing the need for special care instructions.

- Carbon Fiber Production: Polyacrylonitrile is a critical precursor in the production of carbon fibers. PAN fibers undergo a complex series of treatments, including stabilization and carbonization, to convert them into high-strength carbon fibers. Carbon fibers have exceptional mechanical properties, such as high tensile strength, low weight, and corrosion resistance. They find applications in:

- Aerospace and aviation: Carbon fibers are widely used in the aerospace industry for manufacturing aircraft components, satellites, and rockets, owing to their high strength-to-weight ratio.

- Automotive industry: Carbon fiber-reinforced composites are used to produce lightweight automotive parts, leading to improved fuel efficiency and reduced emissions.

- Sporting goods: Carbon fiber materials are employed in the production of bicycles, tennis rackets, golf clubs, and other sports equipment, enhancing performance and durability.

- Water Treatment and Filtration: Polyacrylonitrile is also used in water treatment processes, especially in water purification and wastewater treatment. PAN-based ultrafiltration membranes have several advantages:

- Chemical resistance: PAN membranes show resistance to a wide range of chemicals, making them suitable for various water treatment applications.

- High porosity: PAN membranes can have high porosity, providing excellent filtration efficiency and water permeability.

- Bacterial and particulate removal: PAN membranes can effectively remove bacteria, suspended solids, and other impurities from water, ensuring high-quality drinking water and efficient wastewater treatment.

- Battery Separators: Polyacrylonitrile-based materials are used as separators in lithium-ion batteries. Battery separators play a crucial role in preventing internal short circuits, enhancing the safety and performance of batteries. PAN-based separators offer:

- Thermal stability: PAN separators maintain their integrity even at elevated temperatures, reducing the risk of thermal runaway in batteries.

- Electrolyte wettability: PAN separators exhibit good electrolyte wettability, enabling efficient ion transport within the battery cell.

- Protective Clothing and Gear: PAN fibers are used in the production of protective clothing and gear for various applications, including:

- Fire-resistant clothing: PAN-based fabrics can be treated to provide fire resistance, making them suitable for firefighting and industrial applications where workers are exposed to high-temperature environments.

- Cut-resistant gloves: PAN fibers with high tensile strength are incorporated into gloves used in industries such as metalworking and glass manufacturing to protect against cuts and punctures.

- Ballistic vests: PAN fibers are used in the production of lightweight and high-strength ballistic vests for military and law enforcement personnel.

- Reinforcements for Concrete and Polymers: Polyacrylonitrile fibers are used as reinforcements in concrete and polymer matrices to enhance their mechanical properties. PAN fibers improve:

- Concrete strength: PAN fibers enhance the tensile strength and ductility of concrete, reducing cracking and increasing its durability.

- Polymer composites: PAN fibers are used as reinforcement in polymer composites to enhance their strength, stiffness, and impact resistance, leading to improved performance in various applications.

- Adhesives and Coatings: Polyacrylonitrile is used in the formulation of adhesives and coatings with excellent bonding and protective properties. PAN-based adhesives and coatings are:

- Weather-resistant: PAN coatings offer excellent resistance to weathering, UV radiation, and chemical exposure, making them suitable for outdoor applications.

- Strong bonding: PAN-based adhesives provide strong bonding to various substrates, such as metals, plastics, and composites.

- Medical Applications: Polyacrylonitrile finds applications in the medical sector, particularly in the production of:

- Hemodialysis membranes: PAN-based membranes are used in hemodialysis machines to filter and purify blood for patients with kidney failure.

- Drug delivery systems: PAN-based materials are used in controlled drug release systems, ensuring the gradual release of drugs for improved therapeutic outcomes.

Polyacrylonitrile (PAN) is a versatile polymer with a wide range of applications in different sectors. Its properties, such as chemical resistance, mechanical strength, and thermal stability, make it an attractive material for use in textiles, aerospace, water treatment, battery technology, protective gear, concrete reinforcement, adhesives, coatings, and medical applications. As technology advances and new processing techniques emerge, the potential uses of PAN are likely to expand, further demonstrating its significance across multiple industries.

Product Parameters:

- Molecular Weight: Varies depending on the product form

- Melting Point: Approx. 320°C

- Density: 1.17 - 1.19 g/cm³

- Solubility: Soluble in some organic solvents

- pH: Neutral

Grade Standard: Industrial Grade

Certification: ISO 9001:2015 certified

Purity: 99.5% minimum

Appearance: White to pale yellow solid or fibers

Specifications: As per industry standards and customer requirements

Our Advantages:

- Extensive Industry Experience: With years of experience in the chemical industry, we possess in-depth insights into our customers' needs and provide tailored solutions accordingly.

- High-Quality Products: Our PAN products undergo stringent quality control measures, ensuring that they meet the highest industry standards, guaranteeing exceptional performance and reliability.

- Reliable Supply Chain: With a robust supply chain network, we ensure timely delivery to clients across India, the Middle East, and major cities worldwide.

- Customization: At Vizag Chemical, we take pride in offering flexible customization options in terms of product formulations and packaging, ensuring maximum customer satisfaction.

- Competitive Pricing: We offer competitive pricing without compromising on product quality, providing outstanding value to our esteemed clients.

Production Capacity: Equipped with state-of-the-art manufacturing facilities and streamlined processes, we possess substantial production capacity to meet bulk orders and urgent requirements with ease.

Quality Control: Quality is the cornerstone of our operations. We implement strict quality control measures throughout the production process, ensuring that each batch of PAN products adheres to the required specifications.

Customization: Recognizing that different industries have distinct requirements, we offer flexible customization options in terms of product formulations and packaging.

Company Info: Vizag Chemical is a highly reputed chemical company based in India, committed to delivering top-quality chemicals and polymers to clients across India, the Middle East, and the world. Our customer-centric approach, ethical business practices, and dedication to excellence set us apart in the industry.

Packing: Our PAN products are available in various packaging options, including bulk containers, drums, and bags, ensuring safe transportation and storage.

PHYSICAL PROPERTIES:

- Odor: Odorless

- Boiling Point: Decomposes above 300°C

- Solubility in Water: Negligible

STORAGE: To preserve the integrity of PAN products, it is essential to store them in a cool, dry place, away from direct sunlight and heat sources. Properly sealed containers should be used to prevent moisture absorption.

QUALITY INSPECTION: Each batch of our PAN products undergoes rigorous quality inspection at every stage of the production process, ensuring consistent excellence.

Plant Area: Our advanced manufacturing facility spans a vast area, equipped with cutting-edge technology to produce PAN products efficiently.

Terms of Payment or Quotation & Payment: We offer flexible payment terms and options. For detailed quotations and payment information, please contact our sales team.

Nearest Port: Strategically located in India, Vizag Chemical enjoys easy access to major ports, facilitating seamless export and import operations.

Import & Export Mode: As a dynamic player in the chemical industry, we operate in both import and export modes, catering to the demands of our esteemed international clients.

At Vizag Chemical, we take immense pride in being your trusted supplier, manufacturer, and distributor of high-quality Polyacrylonitrile (PAN) products in India. Our PAN products, backed by stringent quality control measures and extensive customization options, find widespread applications across various industries in India, the Middle East, and major cities worldwide.

With an unwavering commitment to customer satisfaction, a robust supply chain network, and competitive pricing, we have built enduring relationships with clients in top cities across the globe. When you choose Vizag Chemical, you gain access to top-notch PAN products that meet the most stringent industry standards.

Experience excellence in chemical solutions with Vizag Chemical. Contact us today to fulfill your Polyacrylonitrile requirements and witness the impeccable quality and service that sets us apart in the chemical industry.

For inquiries and orders, please get in touch with us at Email-

info@vizagchemical.com

Leave a comment